Facilities and Workflow

standards

Equipment

Instrument and apparatus development

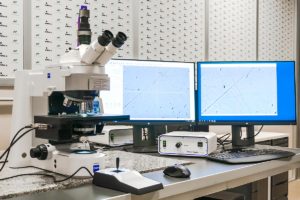

The large optical magnification used in counting of fission tracks (x1000) makes any mechanical vibration of the microscope or the sample to be observed in the resulting image, difficulting the visualization and the operation of the automatic fission track counting software.

To mitigate this problem, LA.TE. ANDES, with Endeavour Ingeniería, developed anti-vibration tables based on an original concept devised by Dr. Ulrich Glasmacher at the University of Heidelberg, Germany.

As a result, pneumatic suspension devices were made, highly effective at eliminating vibrations in the images. The residual vibrations are negligible, even under conditions of maximum magnification and in an environment of severe vibrations.

A direct outcome of this development is the fact that LA.TE. ANDES and Endeavour Ingeniería have a marketable product, very versatile and configurable according to the customer’s need for the isolation of vibrations in microscopes, optical devices, analytical balances and other similar devices.

The drying of samples can be a slow process if it is carried out at ambient air temperatures and flows. To reduce the time of this process and prevent the thermal incursions that can occur with sun drying, as made in other laboratories, an electric dryer was developed that controls the drying temperature of the samples between 20ºC and 40ºC, with constant surrounding air flux.

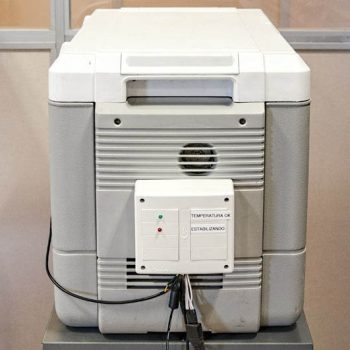

Precise control of temperature of the acid solutions is key in the process of sample etching.

As specified by the test protocol this temperature must be of 20ºC, which can be higher or lower than the ambient temperature, thus making necessary temperature adjustments, heating or cooling the solutions accordingly. Which device allows both processes? A conventional electric heater can only raise the temperature, while a refrigerator can cool it down as the only alternative…

The solution devised was a thermostatic control using an electric cooler that incorporates a Peltier cell, an electrical device capable of dissipating or absorbing thermal power from its environment (thus heating or cooling) according to their electrical feeding polarity. The system incorporates an internal temperature sensor and an embedded system based on an Arduino board that executes the control algorithm to keep the temperature exactly at the desired value, heating or cooling the solution as necessary.